When you first hear the word Pappedeckel, it might not ring any bells—unless you’ve spent time in Germany or have a deep interest in eco-friendly packaging solutions. Literally translating to “cardboard lid” or “paperboard cover” in English, the Pappedeckel is far more than just a piece of packaging material. It is a silent workhorse in our day-to-day lives, protecting products, supporting sustainability, and serving as an underrated symbol of practical design.

This article will take you through everything you need to know about the Pappedeckel: what it is, how it’s made, why it matters, and the surprising roles it plays in industries and households alike

Contents

- 1 What a Pappedeckel Really Is?

- 2 The Role of Pappedeckel in Everyday Life

- 3 A Quick Dive Into the History of Pappedeckel

- 4 Materials and Manufacturing of Pappedeckel

- 5 Pappedeckel and Sustainability: A Natural Fit

- 6 Common Types of Pappedeckel

- 7 Advantages of Using Pappedeckel Over Other Materials

- 8 Pappedeckel in Branding and Marketing

- 9 Challenges and Limitations of Pappedeckel

- 10 The Future of Pappedeckel

- 11 Conclusion

What a Pappedeckel Really Is?

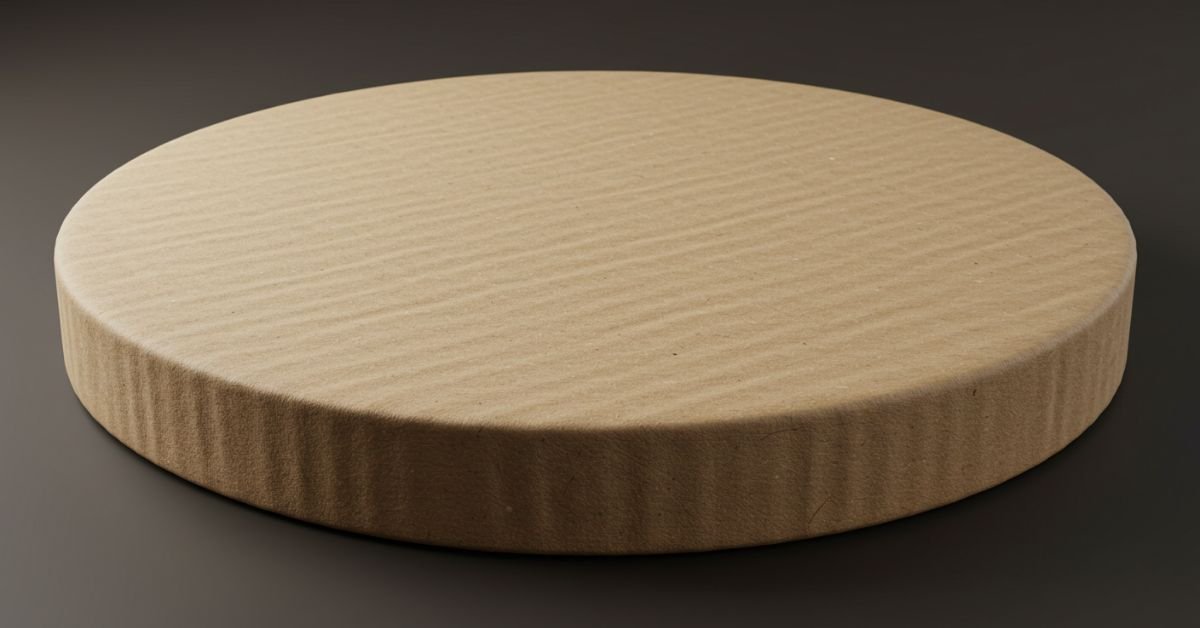

A Pappedeckel is exactly what it sounds like—a lid or cover made from paperboard (thick cardboard). But don’t let the simplicity fool you. This seemingly ordinary piece of material plays a crucial role in packaging, storage, and product presentation. Depending on its design, it can be round, square, rectangular, or even custom-shaped to fit specific containers or boxes.

In many cases, the Pappedeckel is used as the top closure for cups, cartons, or food containers, keeping contents secure and fresh. For example, coffee-to-go cups in Germany often come with a Pappedeckel to prevent spills while still being lightweight and recyclable. In bakeries, it might serve as a protective top for cake boxes or pastry containers.

One of the great things about a Pappedeckel is its versatility. It can be thick and sturdy for heavy-duty packaging, or lightweight and flexible for temporary use. Some even have a laminated surface to resist moisture, grease, or wear, making them perfect for food service applications.

The Role of Pappedeckel in Everyday Life

If you start looking for Pappedeckel in your daily surroundings, you’ll notice them everywhere. At the supermarket, they cover yogurt pots. In cafés, they act as lids for hot drinks. At home, they’re on storage boxes, takeout containers, and sometimes even DIY crafts.

The genius of the Pappedeckel lies in its ability to be functional without being wasteful. Unlike many single-use plastic lids, a cardboard lid can be easily recycled or even composted, depending on the coating and material. This makes it a favorite for eco-conscious brands and customers who want convenience without environmental guilt.

Even in industries beyond food, the Pappedeckel makes appearances. Cosmetic companies use them for premium product packaging, where the lid doubles as a branding surface. Stationery brands often use Pappedeckel designs for pen boxes or gift sets. The common thread? They are practical, affordable, and environmentally smarter than many alternatives

A Quick Dive Into the History of Pappedeckel

While it’s hard to pinpoint the exact moment Pappedeckel became a household item, cardboard-based packaging has been around for centuries. The first documented use of paperboard for packaging dates back to the early 19th century, with the development of machine-made paper in England. Germany, with its long tradition of precision manufacturing and eco-conscious engineering, embraced cardboard solutions early on.

The idea of a removable paper lid likely evolved from wooden and tin covers used in the 1800s. These were gradually replaced by lighter, more affordable cardboard variants as papermaking technology improved. By the mid-20th century, Pappedeckel had become a standard for bakery goods, dairy products, and later, takeaway food and beverages.

Today, with sustainability being a major focus, the Pappedeckel has experienced a revival. While plastic lids dominated for decades, many companies are switching back to cardboard solutions for their lower environmental footprint.

Materials and Manufacturing of Pappedeckel

At its core, a Pappedeckel is made from paperboard—a thick, stiff type of paper. The manufacturing process involves several steps:

a. Raw Material Selection

Manufacturers typically use virgin fibers or recycled paper, depending on the intended use. Food-grade Pappedeckel requires higher purity standards to ensure no contamination.

b. Pressing and Forming

The paper pulp is pressed into large sheets, which are then dried and cut into manageable sizes.

c. Die-Cutting and Shaping

Special machines cut the paperboard into precise lid shapes. These can be flat or slightly domed, depending on the application.

d. Coating and Printing

Some Pappedeckel get a protective coating—such as wax, biodegradable film, or water-based varnish—to resist moisture and grease. Many are also printed with brand logos, product details, or attractive designs.

This process allows for mass production while keeping the end product affordable and customizable

Pappedeckel and Sustainability: A Natural Fit

In the age of climate awareness, the Pappedeckel shines as a champion of eco-friendly design. Unlike plastic lids, which can take hundreds of years to decompose, cardboard lids are biodegradable and often fully recyclable.

When made from recycled paper or sustainably sourced fibers, their carbon footprint is minimal. Plus, advances in eco-coating technology mean they can now be made moisture-resistant without relying on plastic layers.

Governments and environmental organizations are encouraging businesses to adopt such alternatives. In Germany, waste Blowout Taper separation and recycling are deeply ingrained cultural habits, making Pappedeckel a natural fit for the country’s environmental ethos.

Common Types of Pappedeckel

a. Flat Lids – Simple, flat covers used for bakery boxes or product packaging.

b. Domed Lids – Slightly raised to accommodate products like cupcakes or ice cream scoops.

c. Beverage Lids – Designed with a sipping hole or tear-away section for hot drinks.

d. Custom Die-Cut Lids – Shaped to fit unique containers or branding requirements.

The type of Pappedeckel chosen depends on the product type, branding goals, and user convenience.

Advantages of Using Pappedeckel Over Other Materials

Why should businesses choose Pappedeckel instead of plastic, metal, or other lid materials? Here’s why:

- Eco-Friendliness: Fully recyclable and biodegradable when uncoated or coated with eco-friendly layers.

- Cost-Effectiveness: Paperboard is cheaper to produce than many other packaging materials.

- Custom Branding: Easier to print on, making it perfect for logos, promotions, and designs.

- Lightweight: Reduces shipping costs and makes handling easier for customers.

- Versatility: Suitable for food, retail, cosmetics, and more.

This combination of benefits makes Pappedeckel a go-to choice for both large-scale manufacturers and small businesses.

Pappedeckel in Branding and Marketing

One underrated aspect of the Pappedeckel is its marketing potential. That little circle, square, or rectangle sitting on top of your product is valuable advertising space. A clever design can make your packaging stand out on the shelf or in a customer’s hand.

Brands often print eye-catching graphics, QR codes for promotions, or even fun messages to connect with consumers. In the competitive food and beverage market, this simple lid can help foster brand recognition and loyalty.

Small businesses especially benefit from custom-printed Pappedeckel because it gives a professional look without the high costs associated with custom plastic molds or metal stamping

Challenges and Limitations of Pappedeckel

Despite its many strengths, the Pappedeckel isn’t perfect. One major limitation is moisture resistance. Without proper coating, it can warp or weaken when exposed to liquids. This is why coffee cup lids, for example, often require additional waterproofing layers.

Another challenge is structural strength. While perfect for lightweight products, it’s not ideal for heavy or high-pressure packaging situations.

Additionally, improper disposal can still cause waste issues, especially if the lid has a plastic lining that complicates recycling.

The Future of Pappedeckel

The future of the Pappedeckel looks promising, especially as sustainability becomes more than just a trend—it’s now an expectation. We’re seeing innovations like fully compostable coatings, plant-based inks, and even smart Pappedeckel with embedded NFC tags for digital marketing.

As consumer awareness grows, more brands will likely embrace Pappedeckel as part of a holistic eco-packaging strategy. And while it might remain a humble piece of packaging, its role in shaping sustainable commerce is significant.

Conclusion

The Pappedeckel may seem like a small, insignificant item, but its impact on packaging, sustainability, and branding is huge. From your morning coffee to your weekend bakery visit, it’s quietly working in the background—protecting products, reducing plastic waste, and sometimes even making you smile with a clever design