The CES floor this year felt different. The era of focusing solely on build volume and raw print speed appears to be over. In 2026, the additive manufacturing industry has collectively pivoted toward a new metric: invisibility.

The technology is finally moving from the workshop to the home appliance category. Manufacturers are aggressively removing the friction points that have historically plagued the hobbyist experience. The goal is no longer just to print, but to print without constant intervention.

Contents

The End of The Messy Workflow

For years, the handling of photopolymers was the primary barrier to entry. The sticky, toxic nature of the materials made it difficult for average users to adopt the technology. However, CES 2026 showcased enclosed ecosystems that solve this fluid handling problem.

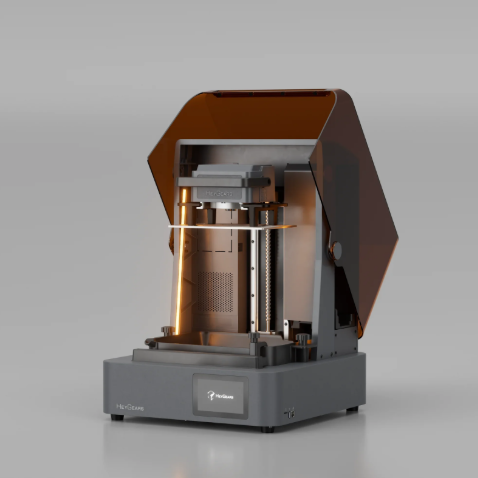

The modern resin printer has evolved into a sealed unit. We observed new cartridge-based systems that automatically dispense material into the vat. These machines monitor fluid levels dynamically, pausing only if a cartridge swap is actually necessary.

Crucially, the post-processing loop is closing. Several prototypes demonstrated built-in washing and curing cycles. The user inserts a sealed resin container and removes a clean, dry part hours later. The chemistry is effectively hidden from the user.

Redefining Flagship Performance

In previous years, the “flagship” label was slapped on any machine with a slightly larger screen or faster stepper motors. That definition has shifted. High specifications are now baseline requirements rather than selling points.

To be considered the best resin 3d printer in the current landscape, a machine must offer autonomous reliability. The standout models at the show featured self-diagnostic routines that run before every print. They check belt tension, screen integrity, and light uniformity without user prompting.

Reliability now trumps theoretical speed. A machine that prints at 300mm/s but fails 20% of the time is no longer acceptable. The market favors systems that guarantee print success through redundant sensors and active calibration.

Intelligent Error Mitigation

The integration of Neural Processing Units (NPUs) into printer mainboards was a major trend. Manufacturers are moving away from simple g-code execution to active, real-time print monitoring.

Micro-Lidar Surface Scanning

Lidar technology has shrunk significantly, finding its way into the print chamber. These sensors scan the build plate after the initial layers are laid down. They generate a topographic map of the adhesion, detecting variances as small as a few microns.

Optical AI Analysis

Cameras are now standard, but their function has changed. Instead of just creating time-lapses, on-board AI analyzes the video feed for failure states. If the system detects spaghetti-ing or layer delamination, it halts the process immediately, saving resin and preventing hardware damage.

Breakthroughs in Material Science

The hardware improvements were matched by significant leaps in chemical engineering. The limitations of standard consumer resins—brittleness and odor—are being addressed at the molecular level.

- Thermal Viscosity Management: New heated vats allow for the use of high-viscosity resins. These thick fluids offer impact resistance comparable to injection-molded plastics.

- Functional Bio-Polymers: We saw plant-based materials that finally meet engineering standards. Unlike early eco-resins, the 2026 variants provide high tensile strength and long-term UV stability.

The Software Ecosystem Maturation

The final piece of the puzzle displayed at CES was connectivity. The standalone machine is becoming a relic. The focus is on seamless cloud integration and fleet management for prosumers.

Slicing is increasingly moving to the cloud. Remote servers handle the complex calculation of supports and orientation, sending a ready-to-print file to the device. This offloads the processing power from the user’s PC and ensures the slicing algorithm is always up to date.

Conclusion

CES 2026 signaled that 3D printing is shedding its “tinkerer only” reputation. The focus on automation, safety, and reliability suggests a maturity in the market.

While the underlying technology remains complex, the user interface is becoming simple. The future of home manufacturing looks less like a science experiment and more like a standard utility.